Laser Soldering

LASER SOLDERING

WITH THE J-CAT STAR GATE LASER SOLDERING ROBOT

J-CAT STAR GATE

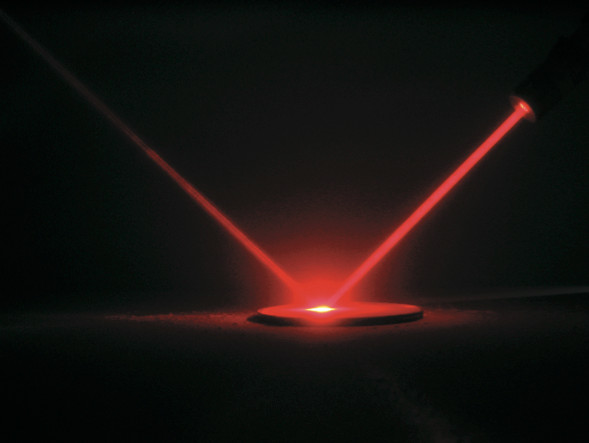

This robot is non-contact soldering; it heats up the target with a high energy light emitted from an oscillated laser diode and is focused with a lens. It is an 80Watt laser with an infrared wavelength of 925nm. The Stargate has has an infrared pyrometer option that provides real-time temperature control.

How Laser Soldering Works And Why You Should Be Interested

Laser soldering is a non-contact process that eliminates the risk of marring or damaging sensitive components. Robots are capable of producing micro-sized laser beams for otherwise difficult applications too small for iron tip soldering. Our advanced optical technology provides a reliable solution for micro and narrow pitched parts used in high-density electronic equipment.

The laser soldering process depends on the type of solder to be used (wire, pre-form or paste). In the case of solder wire, laser irradiation is performed in advance to the joint area (pre-heating). This is the most important process in order to wet and allow the solder to flow easily when supplying the solder wire to the joint area.

Related Technologies

Dispensing

Solder Paste Dispensers

Achieve ultimate small volume stability with precision nozzles. Dispensing technology provides an alternative to the classic wire feed approach. Dispensers allow for a precise amount of solder paste to be evenly distributed in micro amounts. This approach eliminates waste and increases cost effectiveness.

Laser Lenses

Lenses

The type of lens to form a laser beam is composed of two components, the “Input lens” and “Output lens”. With the combination of these lenses, over 100 diameter variations can be achieved.

Looking for solder, iron tips, feeders, cameras, or other supplies?

Visit our

Accessories

or

Consumables

pages.