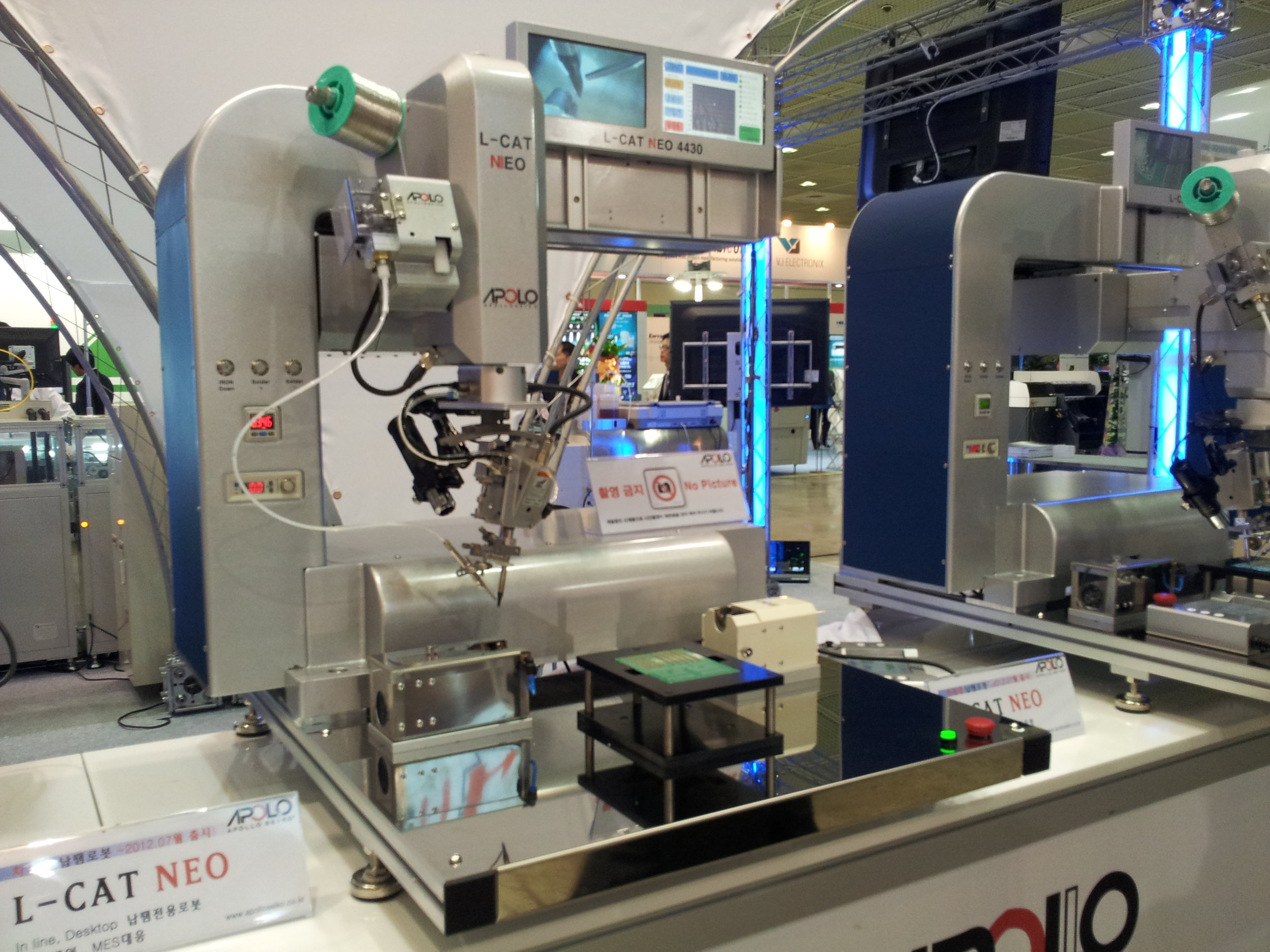

L-CAT NEO-N

L-CAT NEO-N

3RD GENERATION GANTRY-STYLE SOLDER ROBOT

The L-CAT NEO-N is the culmination of over 45 years of experience in the robotic soldering industry.

With this next-generation robot we've directly built in all necessary elements of modern selective soldering. Designed for either an in-line or lean manufacturing process, the L-CAT NEO-N is an exemple of both cutting-edge sophistication and high-speed operation performance.

The built in monitor on the NEO-N allows for viewing the soldering process and aides in programming the application. Robot teaching can be performed by the touch panel Teaching Pendant, a PC or an IPAD. Fiducial recognition and tip position alignment can easily be added to ensure proper tip & PCB alignment. This guarantees an accurate position and ensures the highest quality soldering results.

Key Features

-

Ensure proper tip & PCB alignment with ease. These features guarantee accurate tip positioning and the highest quality soldering results.

-

The built-in monitor allows for immediate viewing of the soldering process and aides in programming the application. Software for the primary application is available fo Windows PC (OS: 7, 8.1, 10). Data management and robot teaching can also be managed from iPhone, iPad, Android, and Windows smartphone devices.

-

Normally soldering robots have a fixed sequence to program solder parameters. However, the L-CAT NEO-N has a very flexible solder sequence that can be customized to meet the needs of your specific application. The L-CAT NEO-N offers flexibility of parameter sequencing to provide solutions for high thermal energy, fine pitch devices, large & small lead combinations etc. The soldering parameters (solder feed amount, feeding speed & temperature) can be arranged in a sequence that provides a solution for each particular soldering challenge.

Looking for solder, iron tips, feeders, cameras, or other supplies?

Visit our

Accessories

or

Consumables

pages.