Zero Solder Ball Feeder

ZSB - Zero Solder Ball Feeder

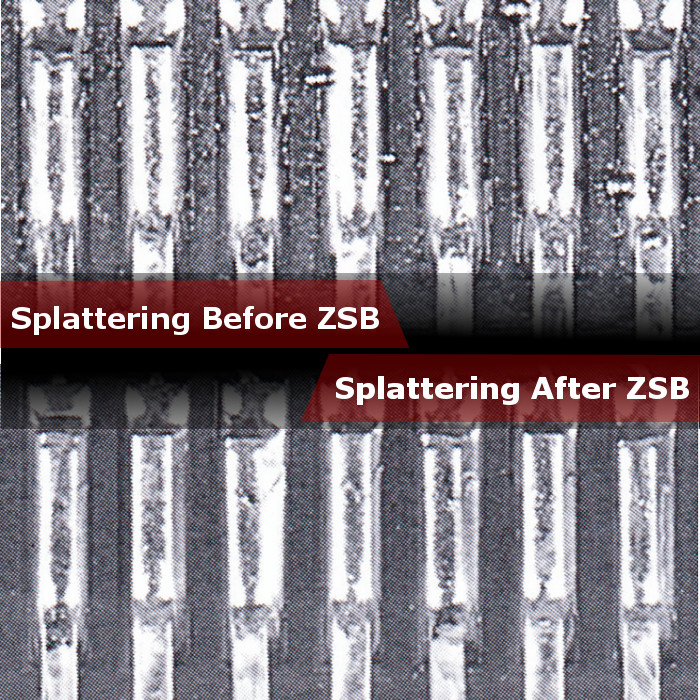

The presence of solder balls during the soldering process are a primary cause of rework and inspection complications, especially in fine-pitch applications. Apollo Seiko's ZSB feeder system eliminates those issues by combating solder ball formation from the start.

The built-in roulette cutting blade makes evenly spaced holes while precisely feeding solder wire. During soldering, flux is released evenly through these holes, providing consistent flux coverage without spattering. The result: solder melts smoothly onto a clean, active surface.

Looking for solder, iron tips, feeders, cameras, or other supplies?

Visit our

Accessories

or

Consumables

pages.